Quality of friction welding

- Top

- Business information

- Machine tool business

- Technical information

- Friction welding machines

- Understand friction welding

- Quality of friction welding

One of the characteristics of friction welding is the high strength and accuracy of the bonded part.

By bringing two workpieces into complete contact with one another and bonding then by heat, oxygen, the archenemy of metal bonding, is pushed outside, realizing high-quality bonding.

Perfect Joints Obtained With Solid State Bonding

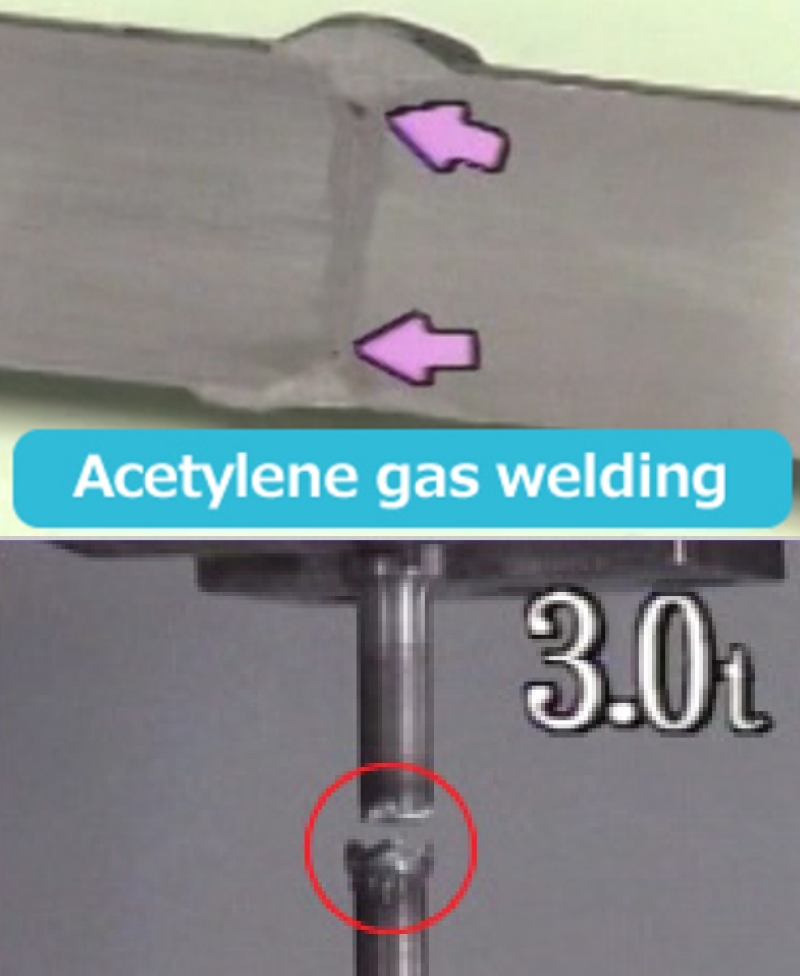

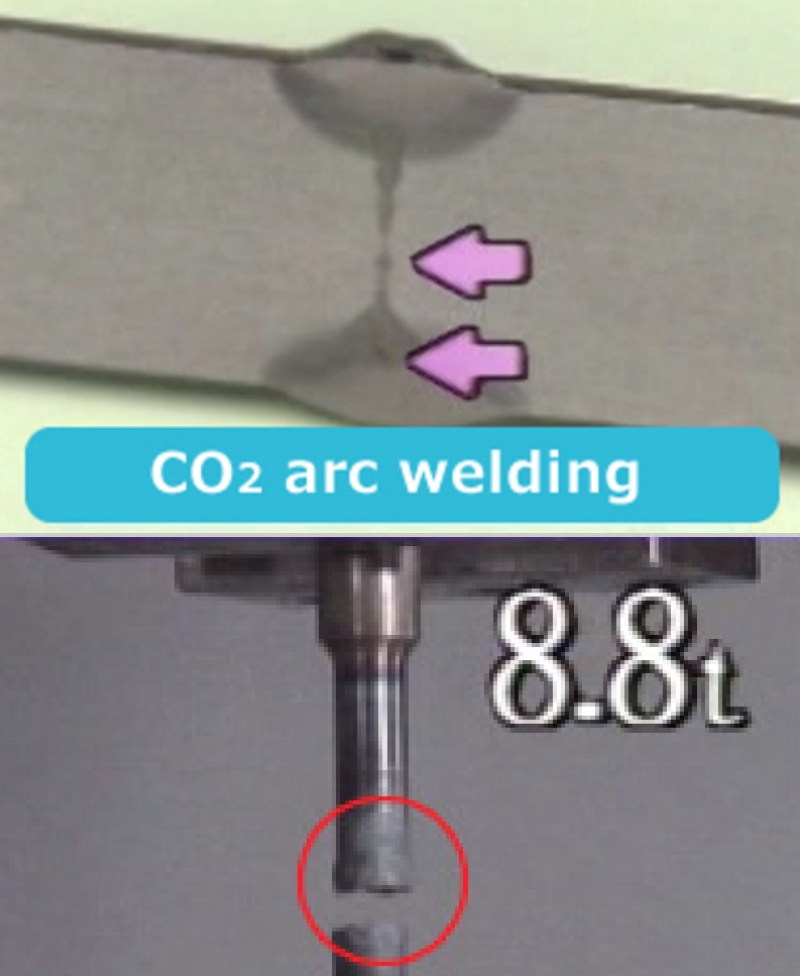

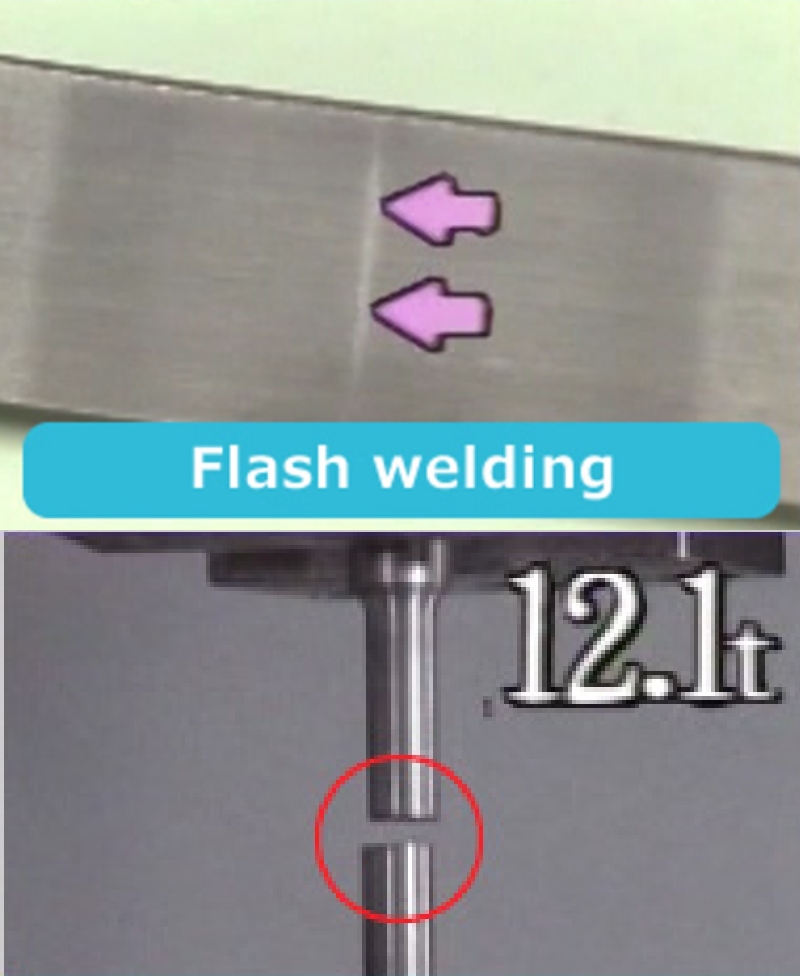

Surprising tensile strength! Stronger pressure welded part than base material

The tensile strength of the friction welding material becomes even stronger than the base material, and fracturing occurred not at the pressure welded part, but at the base material part.

Fracturing at 3.0t

Fracturing at 8.8t

Fracturing at 12.1t

Base material part fracturing at 13.2t

Fracturing at base material part (not pressure welded part) at 13.2t

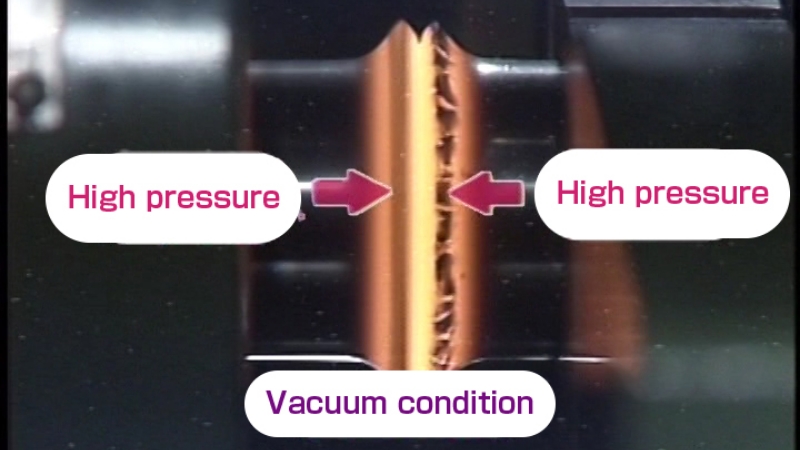

Bonding under same conditions as outer space!

Secret of producing stable high quality

Atmospheric oxygen is the archenemy of metal bonding. If blow holes or pin holes remain in the bonded part, strength may weaken when subjected to bending or pulling, and this may result in rust formation.

With standard welding, the middle part of the material cannot be bonded, and atmospheric oxygen therefore remains. With friction welding, on the other hand, two workpieces are bonded when brought into complete contact with one another. As a result, bonding is carried out under almost the same conditions as in outer space where there is no atmosphere. Impurities such as dirt on the bonding surface, and oxide films, etc. which hinder bonding are pushed out as burrs, ensuring that high-quality products are produced every time.

Furthermore, quality assurance is easy as the control factor is the physical quantity involved. No experience or skill is required.

The fatigue strength is the same as that of the base material!

The fatigue strength of the friction welding material rises a little after friction welding, and once finished, becomes as strong as the base material by then normalizing.

The hardness distribution is the same as that of the base material!

The hardness near the friction welding part rises in the case of material with good hardenability. By performing normalizing, the hardness will be the same as that of the material.

Reliable Quality Assurance

No experience or skill is required!

The most important point in adopting friction welding technology is quality control. Quality assurance is easy as the control factor is the physical quantity involved.