Friction welding machines

- Top

- Business information

- Machine tool business

- Product information

- Friction welding machines

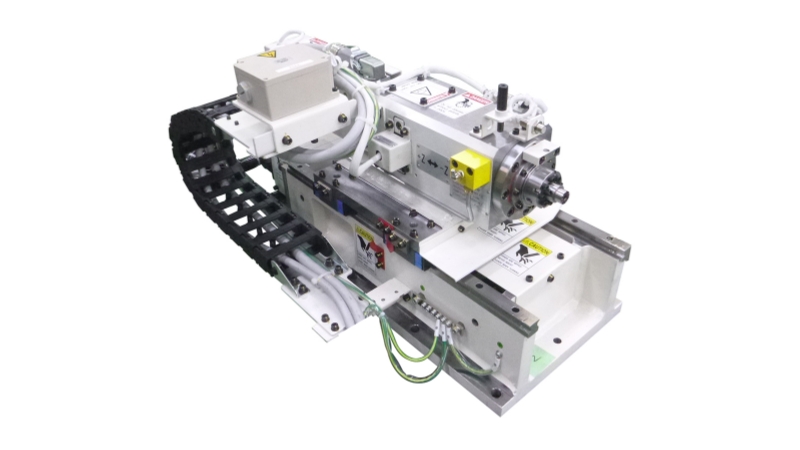

Parts lineup

Model lineup

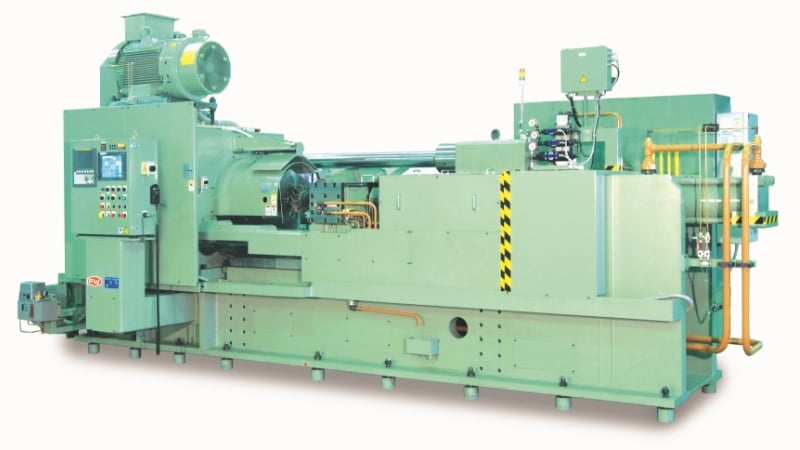

2FW030 series

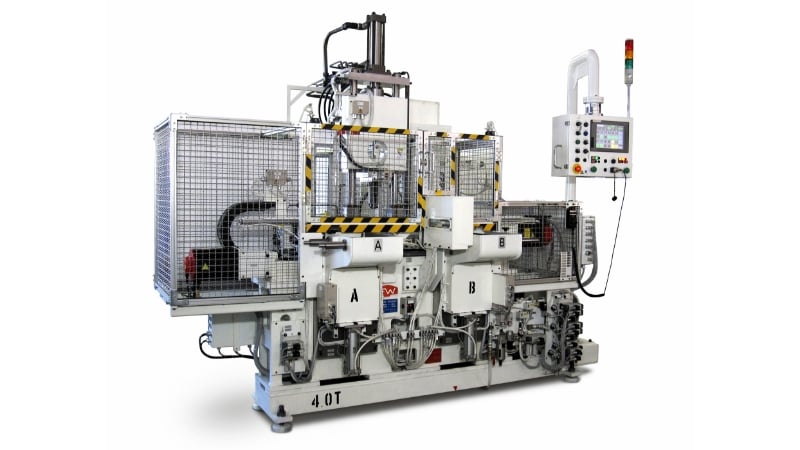

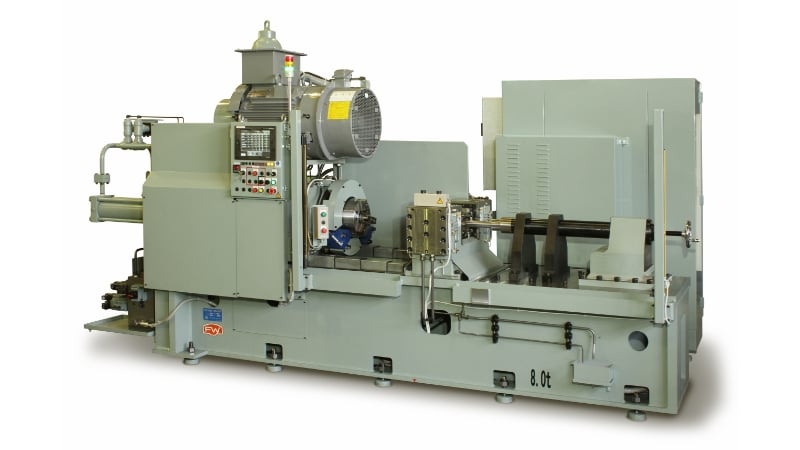

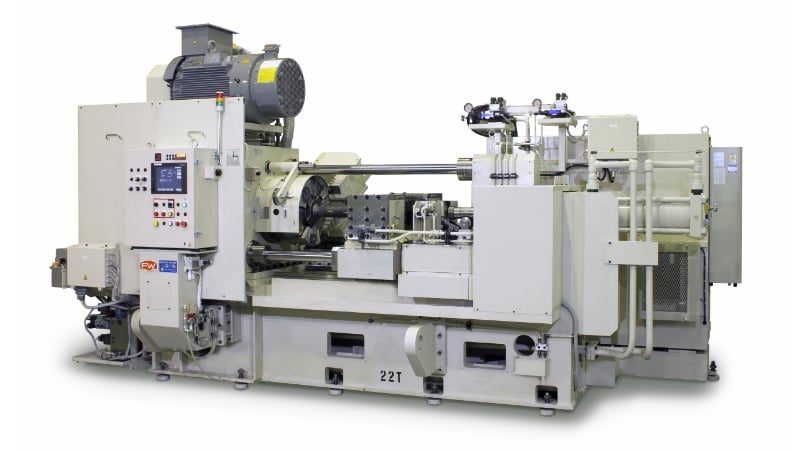

Horizontal single-head machines, Horizontal double-head machines, Vertical machines

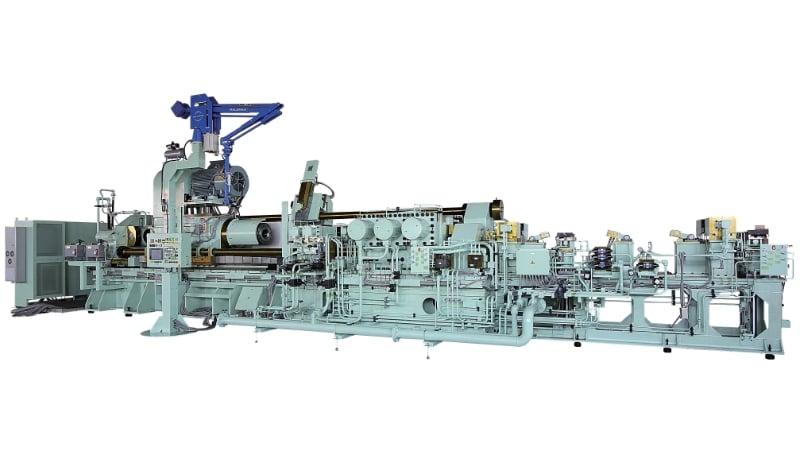

2FW045 series

Horizontal single-head machines, Horizontal double-head machines, Vertical machines