Environmental improvements with friction welding

- Top

- Business information

- Machine tool business

- Technical information

- Friction welding machines

- Understand friction welding

- Environmental improvements with friction welding

As interest in environmental issues have been increasing on a global scale in recent years, initiatives for conservation of the global environment have become a must for corporate activities. Izumi’s friction welding technology also contributes to the conservation of the global environment.

Friction Welding Machines That are Kind to Both People and the Earth

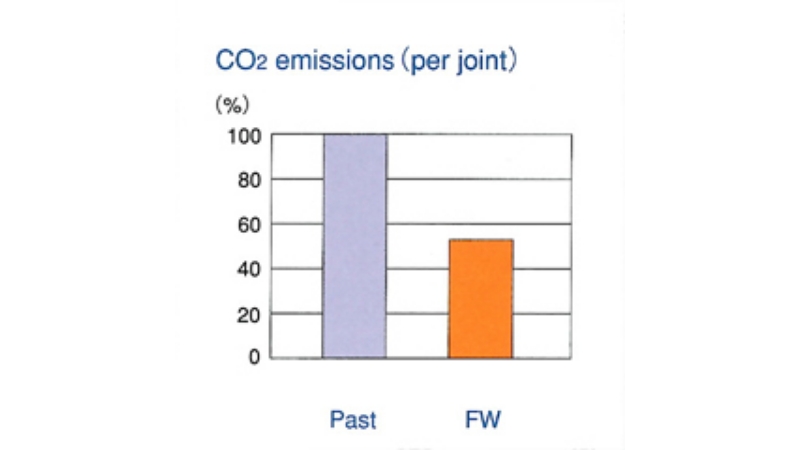

Extremely low CO2 emissions contributing to conservation of the global environment

We compared CO2 emissions produced during CO2 welding and friction welding when bonding a single location on a rear axle tube (ø90 x t5).

| Item | Unit | CO2 arc welding | Friction Welding |

| CO2 gas usage | ㎥ | 0.0162 | 0 |

| Electricity usage | kWh | 0.1583 | 0.1543 |

| CO2 emissions | kg | 0.0352 | 0.0185 |

※47% reduction in CO2 emissions with adoption of friction welding

Good work environment that is also kind to people

Friction welding does not produce spatter or fumes, etc. Furthermore, only negligible amounts of sparks or smoke are produced, helping to realize an extremely good work environment compared to that of conventional welding methods.

Acetylene gas welding

CO2 arc welding

Flash welding