Initiatives for SDGs

- Top

- Corporate information

- Sustainability

- Initiatives for SDGs

Stopping global warming

As a member of the Toyota Industries group, our company is working toward achieving the Toyota Industries’ 7th Environmental Action Plan.

Installing solar panels on the factory roof

As part of our efforts to reduce CO2 emissions, we have been installing solar power generation equipment at the Ishihama Factory since December 2020. Further installation of solar panels was completed in February 2025.

Approximately 20% of the contracted electricity can now be supplemented by solar power generation.And the solar power generation equipment is now able to generate about six times as much electricity as when it was first installed.In addition, a remote monitoring system for the solar power generation equipment has been installed so that the operating status can be monitored in real time. (power generation, abnormality detection, etc.)

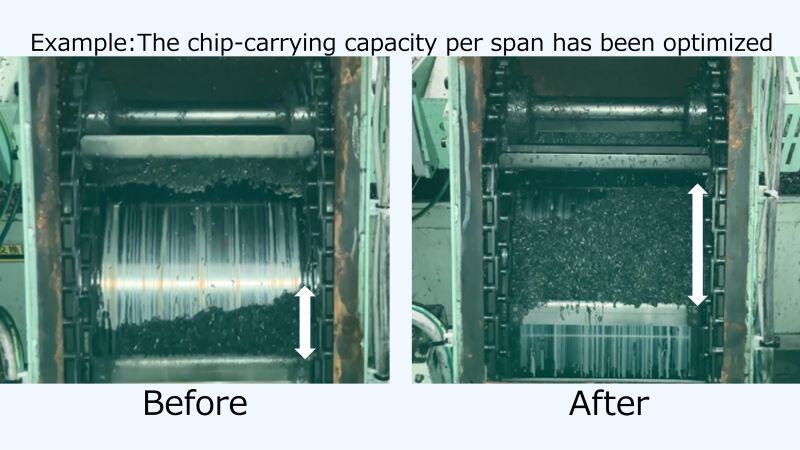

Energy-saving chip conveyor operation and coolant reuse at Ishihama Factory

At the Ishihama Factory, we pursued a 20%reduction in CO2 emissions across our model line between June 2021 and March 2023. As a step, we fine-tuned the chip transport process, optimizing the amount of chips conveyed per interval for equipment with continuous chip conveyor operation. This initiative yielded an impressive 96% reduction in CO2 emissions compared to before improvement. Through the temporary cessation of chip conveyor operations, we successfully curtailed the volume of coolant extracted by the chip cart. Additionally, we have enhanced our coolant management capabilities by capturing all coolant flowing into the collection area. This is achieved by elevating the chip cart with a tilt mechanism.

Switching factory lighting to LED

In order to reduce electricity costs and CO2 emissions, we have updated lighting equipment at all factories from fluorescent lighting to LED. Through the upgrade, we were able to reduce CO2 emissions by 22 tons per year at the Head Office Factory, 78 tons per year at the Kitasaki Factory, and 45 tons per year at the Ishihama Factory.

Visualization of power used at Head Office Factory

Our Head Office Factory is aiming to reduce CO2 emissions to 585 tons by 2025. To move closer to our goal, we installed wattmeters and other devices to monitor the quantity of electricity used by each device at our Head Office Factory. This enables centralized management of electricity consumption. We will work to link this system to energy saving activities.

Reducing power consumption for final cleaning machines at Kitasaki Factory

The Kitasaki Factory is working to reduce CO2 emissions from a model line by 20% by 2025 compared to 2020. As part of these efforts, we brought the final cleaning machine to room temperature and optimized the number of air blower nozzles. This resulted in a 70% reduction in electricity consumption and a 75% reduction in CO2 emissions.

Contribution to and coexistence with local communities

In order to strengthen ties with local communities and contribute to their sustainable development, we participate in volunteer activities such as food drives, traffic safety activities, and blood drives. We will strive to encourage more employees to participate in volunteer activities and increase the number of ways in which we contribute to the local community.